Talent Culture Awards PivotCX the 2023 HR Tech Award

See here: Talent Culture

See here: Talent Culture

Pivot to First explores topics and ideas with the goal of turning hiring into a competitive advantage. In this episode, Mike speaks with Rosey Nathan. In addition to being a podcaster extraordinaire based out of New Zealand, she is a Recruitment Partner with Customise Talent Group. You can also find her work as Career & Whole Human Mentor for Rosey on Recruitment and Career. She also has a varied background in Sales, Management, and recruiting in SaaS, FinTech, and other industries.

In this edition we explore:

Rosey Nathan on the web https://linktr.ee/roseyhercareer

Originally published by Industry Week

Ten years ago, we surveyed manufacturing CEOs to determine what kept them up at night. Coming on the heels of the Great Recession, concerns about another economic downturn were naturally top of mind. Worries about supply chain challenges—in the aftermath of the first significant global supply chain disruption and the Tohoku earthquake and tsunami of March 2011—were second.

We informally surveyed CEOs again this October to gauge their current pain points. Following is a snapshot of top-ranked concerns facing U.S. manufacturing leaders toward the end of 2021.

And yet … according to the Bureau of Economic Analysis, after declining 5% in 2020, corporate profits were up 5% in the first quarter and more than 10% in the second quarter of 2021. Not too shabby considering the growing list of business concerns.

Stephen Gold is president and CEO, Manufacturers Alliance

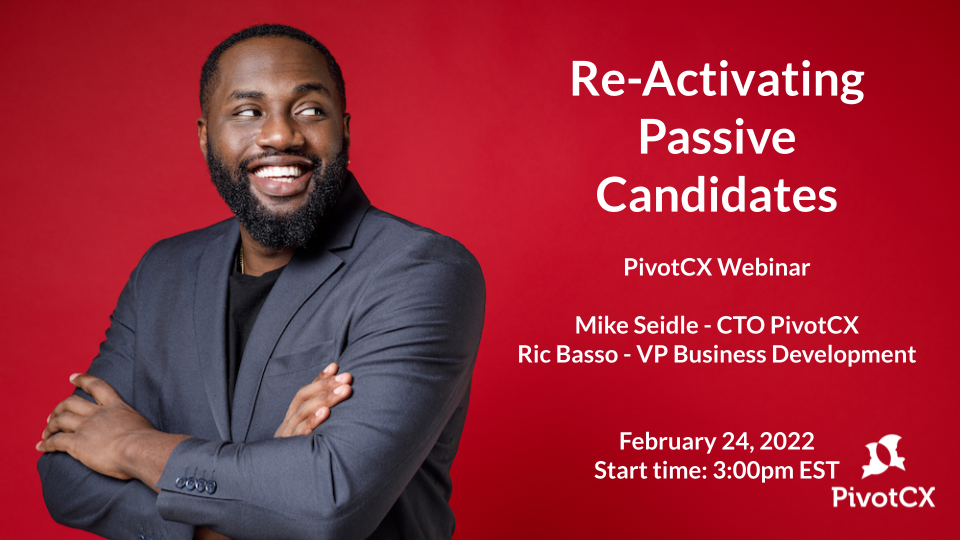

Many employers are experiencing a labor shortage. The previously inexhaustible pools of active candidates have been drying up. Now is the time for many of them to tap into their reserves to reactivate passive candidates.

Mike and Ric will talk about tapping into employers’ hidden market of previous applicants and reactivating passive candidates. Life happens and the timing might not have been right when they first applied, but right now could be the right time! Refresh your talent pipeline and spark new interest in your previous applicants to fill your current openings.

Mike Seidle is a serial entrepreneur and software developer with deep experience in HR Tech. Mike heads up product operations and product development for PivotCX. He brings over 30 years of experience in marketing, software development, product and user experience design, and a proven track record of leading technology-driven teams.

Ric Basso has over 30 years of professional sales management experience, 13 of which have been in the HR Tech space as one of the first 50 employees at Monster.com. As Vice President of Business Development, Ric is a passionate sales and partnerships leader with the personal mission of bringing people together to advance their lives.

Why is it that we obsess about metrics like cost per hire when the cost of not filling a job can literally kill an organization’s bottom line?

HR’s response to the talent shortage? They wouldn’t do anything to the recruiting strategy that would increase the company’s current $700 cost per hire by $50.

Meanwhile, the CEO pointed out the cost of not filling a position, one position, was roughly $19,000 per month in lost revenue. When I heard there were about 1,000 open positions at the company, my jaw dropped.

HR was worried about saving $50 per hire while the opportunity cost per hire was $19,000 per month. The business was losing hundreds of millions in revenue because it wasn’t making hires. But… HR was keeping that cost per hire number under $700. So, save tens of dollars and not make millions.

If your recruiting efforts aren’t keeping pace with your organization’s workforce needs, it may be time to gain a better understanding of what the cost of not making a hire really is. What is that empty seat costing you? What’s that empty mechanic bay costing you? That unfilled nursing slot? The missing restaurant manager? Or that empty hairstylist chair?

In conclusion, if you are in talent acquisition or HR, knowing the cost of not making a hire can make you a rock star to your CEO. When you consider the actual financial impact and lost opportunity, you may find a lot more budget and support for recruiting by framing the problem around the cost of not filling positions. The fact is, unfilled jobs are throttling the growth of most companies, and that’s probably the case at your company, too.

CEOs and CFOs get it.

###

If you are tired of lost hiring opportunities, let’s connect. I’d like to understand the issues your company is facing and how PivotCX can help. Let’s talk about your recruiting.